Plastic products have become a part of our everyday lives, and it's no surprise that injection molding machines are widely used in their manufacture. Injection molding is a process that involves injecting molten plastic into a mold cavity under high pressure. This process is commonly used to create plastic products like combs, toothbrushes, knobs, toys, chairs, and many other items.

Shenzhen Zhongda Plastic Mould Co., Ltd. is a One-stop solution manufacturer based in China, established in 2010. Located in Shenzhen Economic Development Zone, this company offers multiple services including product design, mold design, mold making and injection molding, and assembly products. With years of expertise, their highly skilled team of experts applies the best practices in the manufacturing of top-quality plastic products.

The injection molding process is highly versatile and can make complex shapes with excellent accuracy and repeatability. It is a highly efficient manufacturing process that can produce thousands of identical parts in large quantity. The injection molding process is made up of several components that work together to produce plastic products. The major components of an injection molding machine include:

1. The Injection Unit: The injection unit is responsible for melting and injecting the molten material into the mold.

2. The Clamping Unit: The clamping unit is responsible for holding the mold and applying pressure to keep it closed during the injection process.

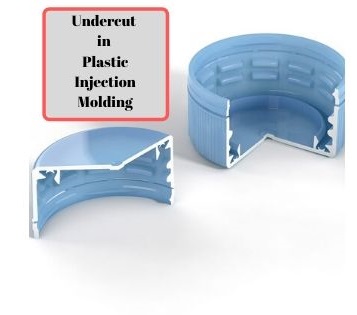

3. The Mold: The mold is the tool that shapes the plastic into the desired form.

4. The Ejector Unit: The ejector unit is responsible for removing the finished part from the mold.

There are different types of injection molding that depend on the type of plastic being processed, the shape of the mold, and other factors. Some of the most common types of injection molding are:

1. High-Pressure Injection Molding: This involves injecting molten plastic into a high-pressure mold cavity.

2. Low-Pressure Injection Molding: This involves injecting plastic into a low-pressure mold cavity.

3. Blow Molding: This process involves creating a hollow plastic item by using a blow mold.

4. Extrusion Molding: This process involves extruding molten plastic into a continuous shape.

Injection molding can use a variety of plastics, including ABS, polycarbonate, polyethylene, polypropylene, and others. Each plastic has its unique characteristics that influence the choice of material for a particular product. The injection molding process can also incorporate different additives, such as fillers or pigments, to change the properties of the final product.

In conclusion, injection molding is a highly efficient and versatile process that plays a crucial role in the manufacturing of plastic products. Shenzhen Zhongda Plastic Mould Co., Ltd. offers a one-stop solution for manufacturers looking to produce top-quality plastic products. By combining expertise in product design, mold design, mold making, and injection molding, this company offers a comprehensive range of services to meet the needs of their clients. With their years of experience, Shenzhen Zhongda Plastic Mould Co., Ltd. is the ideal partner for manufacturers looking to produce top-quality plastic products.