Introduction:

In the field of plastic manufacturing, injection molding stands as one of the highly efficient and effective processes. This technology offers a range of possibilities for manufacturing different parts and components, making it a popular choice for industries worldwide.

One vital component that plays a significant role in the injection molding process is the sprue bush design. The design of the sprue bush plays a crucial role in maintaining high-quality plastic parts.

In this blog, we will delve deeper into the sprue bush design in plastic injection molds and highlight its importance in the injection molding process.

Melt Flow Passageway:

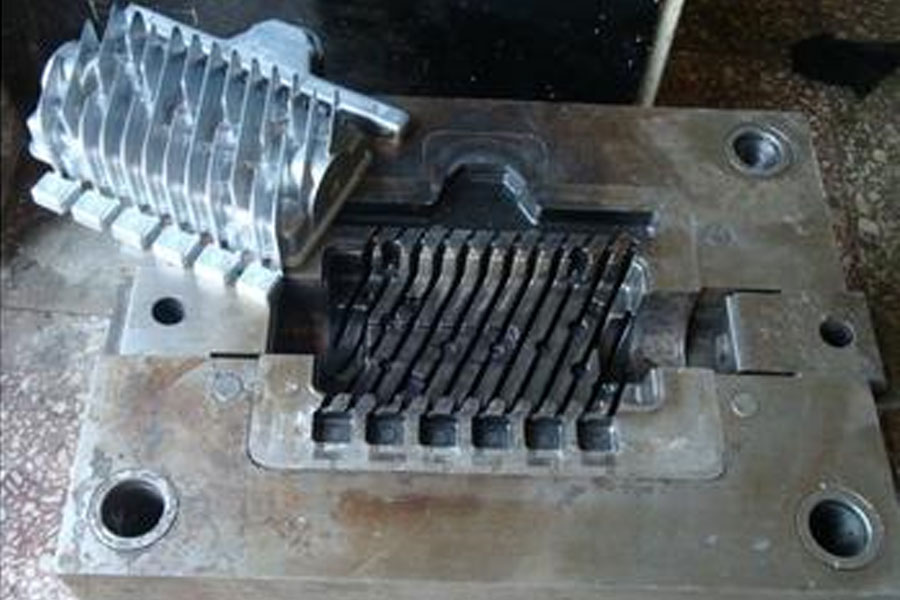

As mentioned earlier, the sprue bush is the melt flow passageway that connects the injection molding machine nozzle to the starting point of the branch runner. The melt flow passageway is a vital component in the injection molding process, as it provides the channel for molten plastic to fill the mold cavity.

The design of the sprue bush should be such that it effectively delivers the molten plastic from the injection molding machine nozzle into the mold cavity. It is important to note that the size of the sprue bush should be proportional to the volume of the mold cavity.

Runner System:

The sprue bush design and the runner system in an injection mold are interdependent. The runner system refers to the passageway that connects the sprue bush to the mold cavity. The design of the sprue bush will impact the design of the runner system.

The runner system should have a consistent cross-sectional area for controlling the flow rate of plastic. Any variations in the cross-sectional area can lead to uneven filling, resulting in defective parts.

Mold Cooling System:

The sprue bush design also plays a crucial role in the mold cooling system. As the molten plastic flows through the sprue bush and the runner system, it undergoes a cooling process.

The design of the sprue bush should ensure that the molten plastic is evenly distributed in the runner system. This ensures that the cooling process is consistent, resulting in well-formed plastic parts.

Material Selection:

The material selection for the sprue bush is also vital in ensuring that the plastic parts meet the required standards. The sprue bush should be made from materials that can withstand high temperatures and pressures.

The material selection should also consider factors such as wear resistance, corrosion resistance, and durability. Choosing the right material for the sprue bush ensures that it lasts longer and delivers high-quality parts.

Holes And Threads:

The design of the sprue bush should also consider the placement of holes and threads. Holes are essential for venting trapped air during the filling process. Proper placement of holes ensures that the air can escape without affecting the plastic flow.

Threads are also important for attaching the sprue bush to the injection molding machine nozzle firmly. The threads should be compatible with the threading on the injection molding machine nozzle to ensure a tight seal.

Design Optimization:

Optimizing the sprue bush design is crucial in achieving high-quality plastic parts. The design should consider various factors such as the volume of the mold cavity, the runner system, and the mold cooling system.

The design should also consider the material selection, placement of holes and threads, and the overall functionality of the injection mold.

Conclusion:

The sprue bush design is, without a doubt, a critical component in the injection molding process. Its design plays a crucial role in ensuring the consistent flow of molten plastic into the mold cavity.

Optimizing the sprue bush design ensures that the plastic parts produced are of high quality and consistent in shape and size. The design of the sprue bush should also consider the runner system, mold cooling system, material selection, holes and threads, and overall functionality of the injection mold.

If you are planning to produce plastic parts through injection molding, be sure to consider the sprue bush design. Working with a reputable injection molding company can help you achieve the best design for your injection mold.