| Mold Material | 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mold Type | Plastic Injection Molding |

| Product Material | ABS, PA, PA66+GF, POM, PC, PP, PET, TPE, PVC, HDPE, etc |

| Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

| Injection Mold Machine | 19 Sets With Model 90T to 1100T |

| Gate Type | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Runner Type | Cold Runner or Hot Runner |

| Cavity | Single or Multi cavities |

| Mold Life | 45#:50,000 to 100,000 shots P20:100,000 to 200,000 shots 718: 200,000 to 300,000 shots H13: 300,000 to 500,000 shots |

| Lead Time | Generally mold making will take around 30 days and 7-10 day to mass production |

| Package | Wooden packing box for molds and Generally inner packed in opp bags, outside packed in standard export carton with shipping marks, and the cartons will be full of bubble bags. |

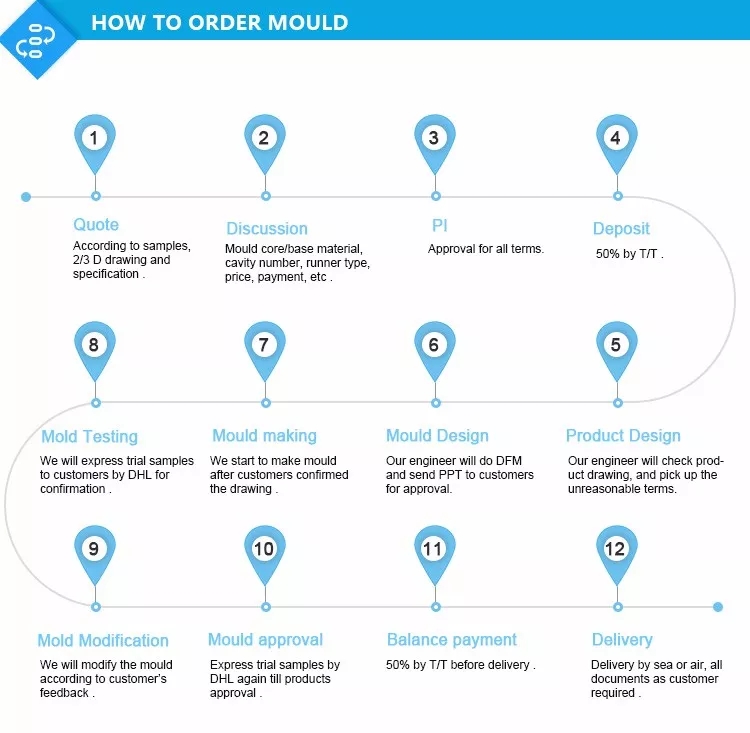

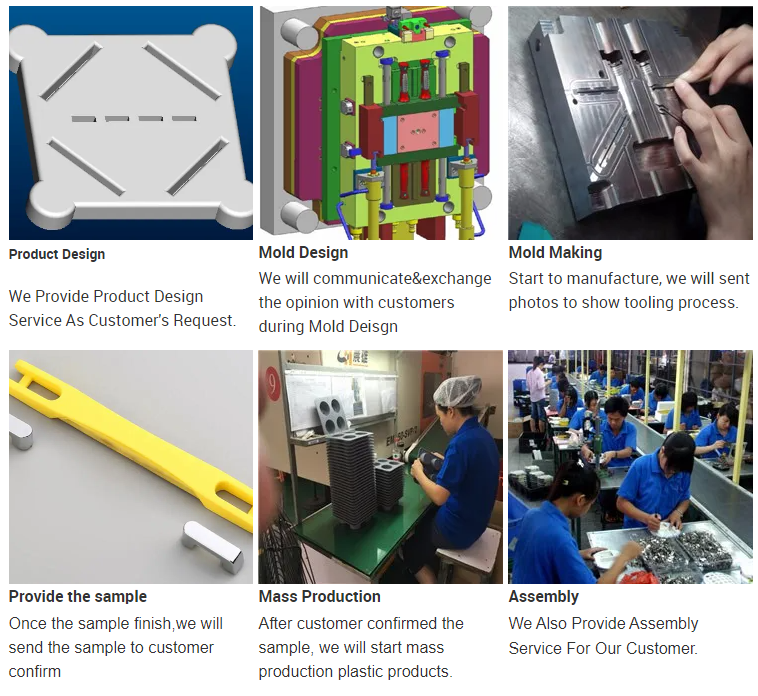

RFQ: Q: How many molds could you make every month? A: About 60sets Q: How about the largest mold you ever made? A: 2000*1600*1000mm Q: How about the tolerance? A: Mold tolerance 0.01mm, Product 0.01mm Q: Could you make double color injection mold? A: YES,We help many clients making their double color injection mold. Q: What do you need for the quotation? A: We need 2D product drawing&3D file, or specific sample with detailed explanation and mold sepcification Q: How about the steel you usually use? A: We only use standard components form LKM,DAIDO, HASCO, DME Q: What is your turnaround time for injection mold buiilding? A: Usually 3-5 weeks, it also depends on mold zide and structure complexity. We can overwork for your urgent project to shorten the delivery. High Quality Injection Mold, Injection Mold For Plastic Parts, Injection Molded Parts, Injection Molds Molding Parts Service, Plastic Custom Part, Plastic Injection Mold Makers, Plastic Injection Parts ,plastic part manufacture

RFQ: Q: How many molds could you make every month? A: About 60sets Q: How about the largest mold you ever made? A: 2000*1600*1000mm Q: How about the tolerance? A: Mold tolerance 0.01mm, Product 0.01mm Q: Could you make double color injection mold? A: YES,We help many clients making their double color injection mold. Q: What do you need for the quotation? A: We need 2D product drawing&3D file, or specific sample with detailed explanation and mold sepcification Q: How about the steel you usually use? A: We only use standard components form LKM,DAIDO, HASCO, DME Q: What is your turnaround time for injection mold buiilding? A: Usually 3-5 weeks, it also depends on mold zide and structure complexity. We can overwork for your urgent project to shorten the delivery. High Quality Injection Mold, Injection Mold For Plastic Parts, Injection Molded Parts, Injection Molds Molding Parts Service, Plastic Custom Part, Plastic Injection Mold Makers, Plastic Injection Parts ,plastic part manufacture