Introduction:

Plastic injection molding and assembly processes play a crucial role in the manufacturing industry, enabling the production of high-quality, precise, and reliable parts. The Engineering Group at Texas Injection Molding is dedicated to developing, documenting, and monitoring production processes to ensure consistent and dependable part quality. This blog aims to shed light on the significance of injection molding and assembly services, while highlighting the key role played by Texas Injection Molding in this field.

1. Understanding the Basics of Plastic Injection Molding:

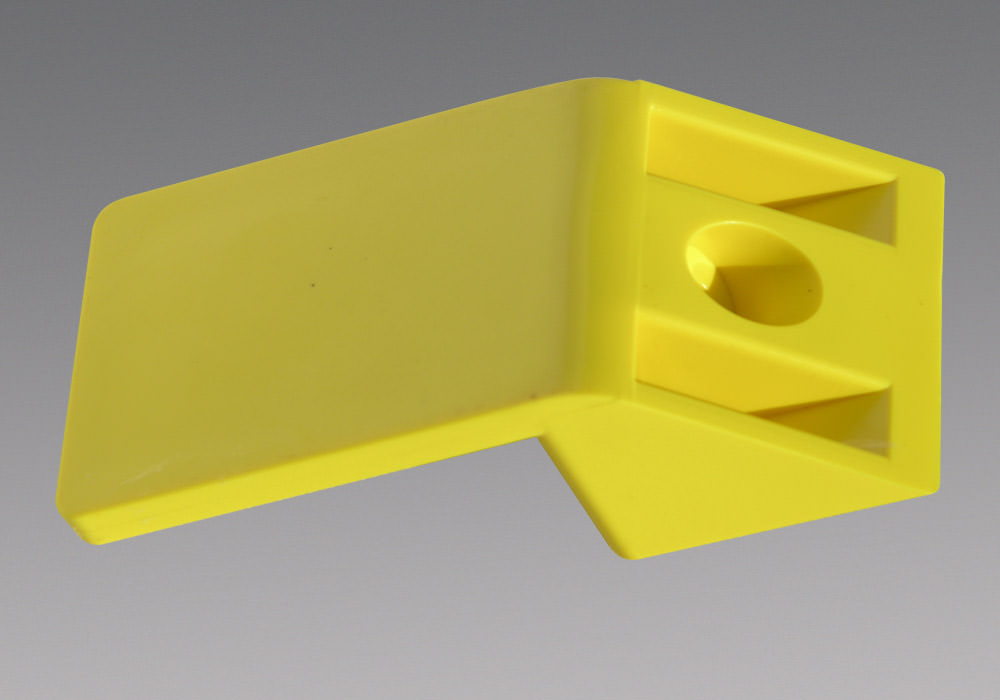

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity, allowing it to cool and solidify into a desired shape. This process offers remarkable versatility, enabling the production of complex geometries with high accuracy. Texas Injection Molding operates a range of injection molding machines, varying in tonnage and shot capacity, to accommodate diverse project requirements.

2. The Importance of Repeatable and Dependable Part Quality:

Ensuring consistent part quality from shot to shot is of paramount importance in the manufacturing industry. Texas Injection Molding's Engineering Group focuses on developing robust production processes that guarantee repeatable and dependable part quality. By thoroughly documenting these processes, they provide the necessary guidelines for consistent manufacturing, eliminating inconsistencies and defects.

3. Materials and Capabilities:

Texas Injection Molding offers a wide range of materials suitable for injection molding and assembly processes. These include High-Density Polyethylene (HDPE), Acrylonitrile Butadiene Styrene (ABS), and many more. Their varied capabilities allow them to cater to diverse industry needs, enabling the production of parts for various applications.

4. Importance of Assembly Services:

Assembly is a critical step following the injection molding process since many products are composed of multiple components. Texas Injection Molding provides exceptional assembly services, ensuring seamless integration of various parts to create final products. This streamlined approach saves time, reduces costs, and simplifies the manufacturing process.

5. Advantages of Injection Molding and Assembly:

Injection molding and assembly services offer several notable advantages. The high precision and accuracy achieved through injection molding result in consistent part dimensions and improved product performance. Moreover, the use of advanced materials enhances durability and resistance to environmental factors. Combining injection molding with efficient assembly processes further enhances production efficiency, reducing overall manufacturing time.

6. Maximizing SEO Opportunities:

In order to maximize the reach and visibility of this blog, specific keyword optimization is crucial. Incorporating relevant keywords like "injection molding" and "assembly" throughout the content enhances its search engine optimization (SEO). This enables the blog to rank higher in search engine results and attract targeted traffic interested in plastic injection molding and assembly services.

Conclusion:

Plastic injection molding and assembly services provided by Texas Injection Molding are vital for ensuring repeatable, dependable part quality. Their expertise in developing, documenting, and monitoring production processes allows for the creation of high-quality parts shot after shot. By incorporating injection molding and efficient assembly practices, manufacturers can achieve enhanced precision, durability, and productivity. Whether it's creating intricate components or assembling multi-part products, Texas Injection Molding remains a trusted partner in the plastic injection molding industry.