- In the service of plastic injection, Ideal plastic is more than just an injection molder.

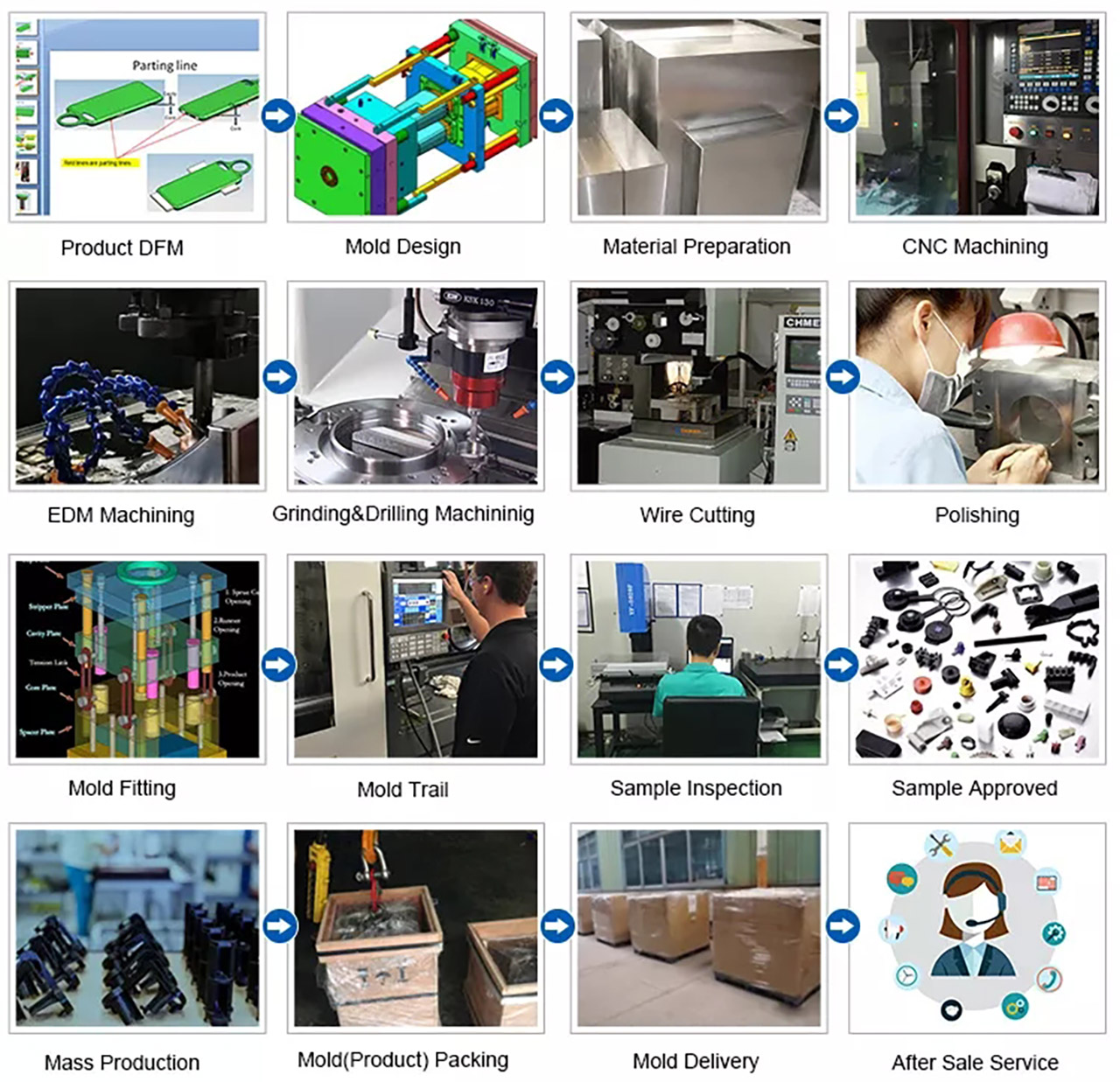

- We provide solutions to manufacturing from start to finish.

- Our expertise enables us to provide clients with superior product by providing the

- highest quality in design, development, and solutions for precision injection molding and related manufacturing.

- We have over 10 years production experience.

Zhongda Mould is a One stop solution manufacturer based in Shenzhen China. We are able to offer multiple services: product design,mold design,mold making and injection molding.assembly products. We focus on project development from design to products.help client developped thousands of project these years,this is one of our biggest advantages,we can make your dream truth once get your idea.