| Items | Custom high precision plastic injection parts |

| color | white,black,green,nature,blue,yellow,etc |

| material | ABS,PMMA,PC,PP,PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE,etc |

| mould cavity | single cavity & multi cavity |

| runner system | hot runner and cold runner |

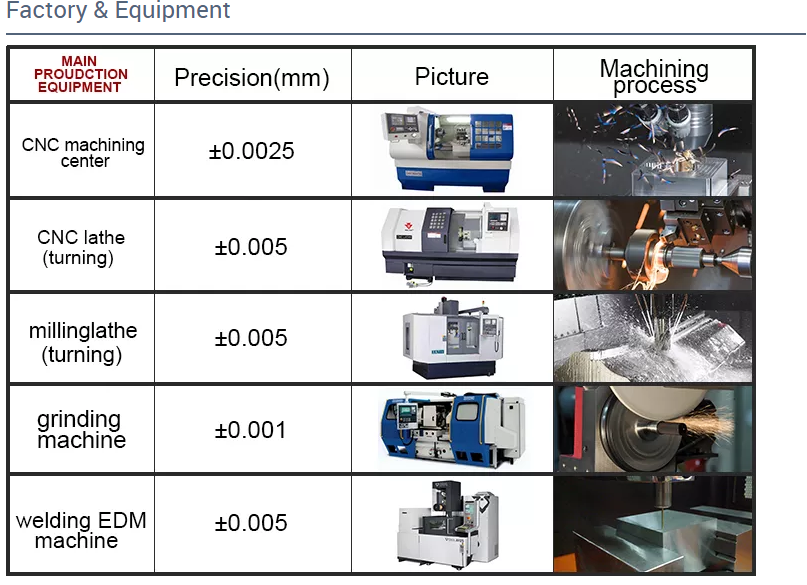

| equipment | CNC, EDM, cutting off machine,plastic machinery etc |

| mould material | P20/ 718H/ S136H/ S136 hardened/ NAK80 |

| injection machine | 88T, 90T, 120T, 168T, 200T, 380T,420T,1200T |

| mould life | 500000-5000000 shots as per customers' requirement |

| size | 5-1000mm,or customized |

| tolerance | ± 0.005mm |

| shape | as per your drawing or the sample |

| free sample | available |

| advantage | one stop procurement |

| Application field | Various plastic injection molded parts for various industrial and automotive applications |

| lead time | 15-30 days for mould,plastic products according to quantity |

|

other | 24 hours instant and comfortable customer service |

| shipping status notification during delivery | |

| regular notification of new styles & hot selling style |

A: We are direct factory with more than 10years experienced engineers and more than 100 employees as well approximate 3,500 square workshop area.A: We will submit the quotation in 24 hours if getting detailed information during warking days. In order to quote for you earlier, please provide us the following information together with your inquiry: 1. 3D Step of Files and 2D Drawings 2. Material requirement 3. Surface treatment 4. Quantity (per order/per month/annual) 5. Any special demands or requirements, such as packing, labels, delivery, etc.A: We pack the plastic moulds with wooden box. There are the main 3 operation steps. First Step: We daub some rust preventive oil on the mold. Second step: We pack the mold with thin plastic film to avoid moisture. Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.A: Yes we offer free sample but do not afford the shipping cost.

A: We are direct factory with more than 10years experienced engineers and more than 100 employees as well approximate 3,500 square workshop area.A: We will submit the quotation in 24 hours if getting detailed information during warking days. In order to quote for you earlier, please provide us the following information together with your inquiry: 1. 3D Step of Files and 2D Drawings 2. Material requirement 3. Surface treatment 4. Quantity (per order/per month/annual) 5. Any special demands or requirements, such as packing, labels, delivery, etc.A: We pack the plastic moulds with wooden box. There are the main 3 operation steps. First Step: We daub some rust preventive oil on the mold. Second step: We pack the mold with thin plastic film to avoid moisture. Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.A: Yes we offer free sample but do not afford the shipping cost.

A: 3C certification, REACH,ROHS,PRO65.A: We offer products design and 3D print service, we have 15 injection machines and 2 assembly lines, we can provide production run and assembly service.A: We provide after-sales service within two years after customer receive the mold. If the mold is damaged within two years, we can send the new replacement mold fittings for free.

A: 3C certification, REACH,ROHS,PRO65.A: We offer products design and 3D print service, we have 15 injection machines and 2 assembly lines, we can provide production run and assembly service.A: We provide after-sales service within two years after customer receive the mold. If the mold is damaged within two years, we can send the new replacement mold fittings for free.