| Product Description | ODM plastic injection molding |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Quality: | RoSH and CE standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

| Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

| Experience: | Over 10 years experience in plastic injection mold making and plastic prouducts produce. |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 800-1200Tavailable. |

1. Experience

Since the company was established in 2012, we have more than 10 years of experience in the field of plastic injection mold and injection parts.

2.Design Ability

We have an excellent Design Team, 11 senior engineers work on different projects.We listen voice from our clients and give them good advice to make sure the production more economic and efficient, also makes the product more functional.

3.Good Communication

Communication is one of the most important factors in our cooperation. Our sales and engineers can best grasp the demands of customers, understand their intentions, and provide the best products to them

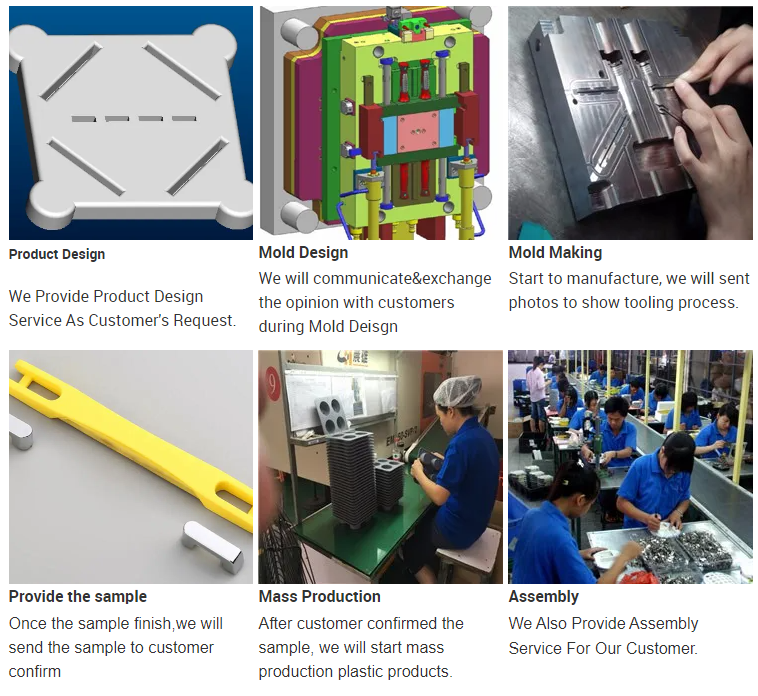

4.One Stop Service

We have not only die-casting production, but also design and assembly capabilities. We can source parts according to customer demands and assemble finished products for shipment

5.Quality Control

Our quality control includes IQC(incoming quality control), PQC(production quality control) and FQC(final quality control). With QC report for every batch of production, all production data is recoreded in our ERP system.

6.Fast delivery

We do plan and time table for projects, so it’s no need to worry about delivery, also We have ability to handle urgent orders.

FAQ: Q1:Where can I get product&price information? A1:Send us e-mail or online talk , we will contact you soon as we receive your news.24/7 service for you. Q2: How soon can I get samples? A2: Depending on your specific project, it usually takes 10 to 20 days. Q3:How to enjoy the OEM services? A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you. Q4:Can you make machining parts based on our samples? A4:Yes, we can make measurement based on your samples to make drawings for machining parts making. Q5: Is it possible to know how are my products going on without visiting your company? A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress

FAQ: Q1:Where can I get product&price information? A1:Send us e-mail or online talk , we will contact you soon as we receive your news.24/7 service for you. Q2: How soon can I get samples? A2: Depending on your specific project, it usually takes 10 to 20 days. Q3:How to enjoy the OEM services? A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you. Q4:Can you make machining parts based on our samples? A4:Yes, we can make measurement based on your samples to make drawings for machining parts making. Q5: Is it possible to know how are my products going on without visiting your company? A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress