Injection molding is a widely used manufacturing process for forming plastic products. The process involves the melting of plastic pellets or granules and injecting them into a mold cavity to form a desired shape. At Composite Resources, we have perfected the injection molding technique with our hot runner injection molding machines.

Our hot runner injection molding machines use a heating mechanism to ensure that the plastic material stays in its molten state for a longer period of time. This helps us to reduce the production time and eliminate waste. With our unique injection molding design, we also eliminate the need for secondary processing, thereby reducing the cost of production.

At Shenzhen Zhongda Plastic Mould Co., Ltd., we offer a one-stop solution to our clients’ needs. With our expertise in product design, mold design, mold making, and injection molding, we are able to provide quality products to our clients. We are based in Shenzhen Economic Development Zone, China, and have been operational since 2010.

Our injection molding process starts with the design of the product. We work closely with our clients to ensure that the product meets their specifications. Our experienced designers then create a mold design that is used to develop the mold for the injection molding process.

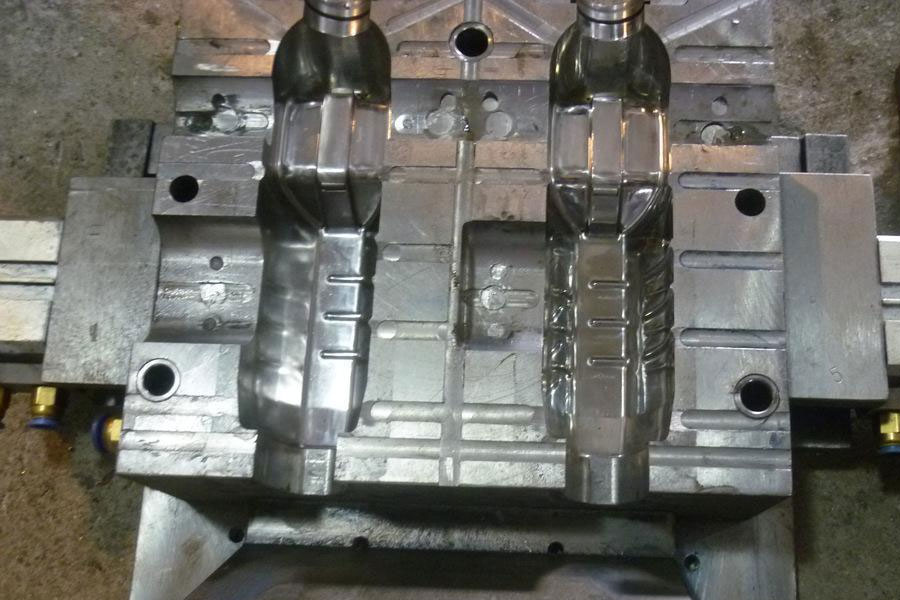

We use state-of-the-art equipment and technology to produce high-quality molds. Our molds are made from durable materials and can withstand high pressures and temperatures. This ensures that we produce quality products that meet our clients’ requirements.

In the injection molding process, we use our hot runner injection molding machines to inject the melted plastic material into the mold cavity. The machines use a heating mechanism and a series of nozzles to ensure that the plastic material flows evenly into the mold cavity. After the plastic material solidifies, we open the mold and remove the product.

At Shenzhen Zhongda Plastic Mould Co., Ltd., we also offer assembly services for our clients. We can assemble the products and package them according to our clients’ requirements. This ensures that our clients receive a finished product that is ready for use.

In conclusion, the injection molding process is a fast and cost-effective way to produce plastic products. At Composite Resources, we have perfected the injection molding technique with our hot runner injection molding machines. At Shenzhen Zhongda Plastic Mould Co., Ltd., we offer a one-stop solution to our clients’ needs, from product design to mold making and injection molding. Contact us today for all your plastic injection molding needs.